Ask Your Questions

Home / Product / Product details

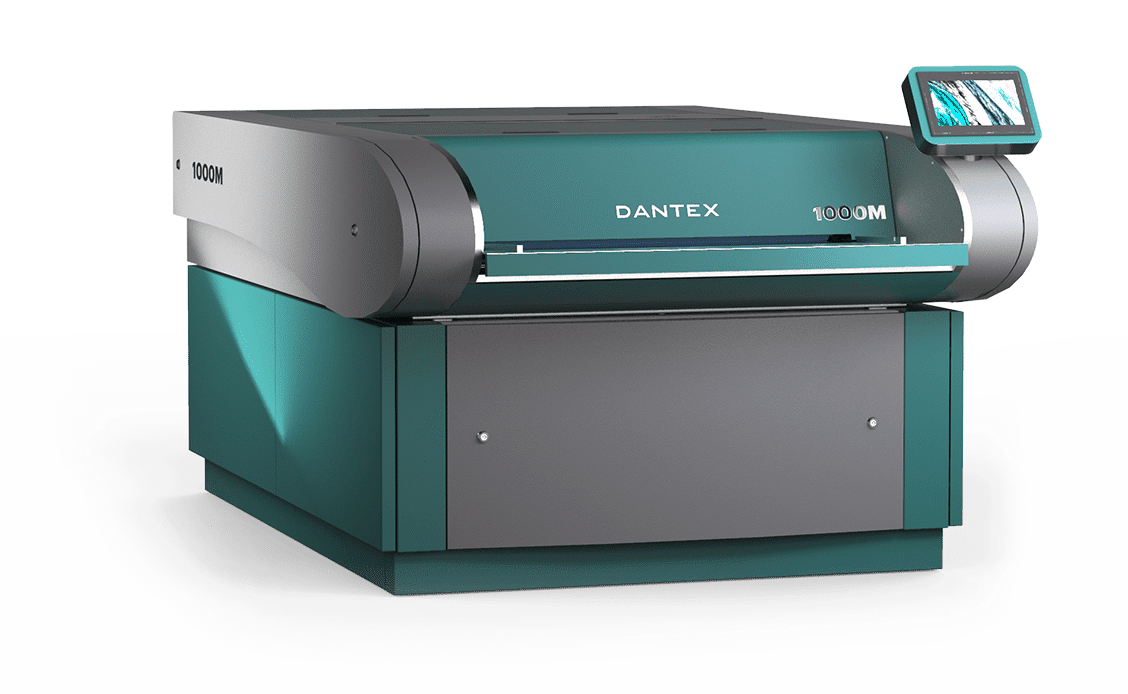

Marathon Automatic Letterpress Processing Systems

Marathon Automatic Letterpress Processing Systems

The Marathon Series represents the next generation of automatic letterpress plate processing technology. Designed and engineered by Dantex, this system delivers unparalleled speed, quality, and sustainability for the modern metal decorating and packaging industries.

Models Available

- Marathon 1000M – Maximum plate size: 900 mm x 1200 mm (35.43” x 47.24”)

- Marathon 600M – Maximum plate size: 580 mm x 1200 mm (22.83” x 47.24”)

Both models are built to handle a wide range of production demands while maintaining precise consistency and long-term reliability.

Key Features & Advantages

- Ultra-High Speed Washout – Achieve faster processing times with advanced washout technology designed for high-volume production.

- True Solvent-Free System – Environmentally friendly design that eliminates the need for solvents, ensuring a cleaner, greener workflow.

- Low Energy Consumption – Engineered to reduce power use, lowering overall operational costs.

- Up to 80% Less Water Usage – Innovative water management system contributes to sustainability and efficiency.

- Up to 75% Energy Savings – Optimized system architecture delivers exceptional performance while minimizing energy draw.

- Automatic Brush Head Lifting System – Ensures smooth, safe handling and prolongs equipment life.

- Optional LED Exposure System – Available for improved plate exposure and faster turnaround times.

- Soft, Gentle Wash for Quality Maintenance – Protects fine image details and extends plate life.

- Integrated Black Mask Removal System – Provides a cleaner and faster prepress workflow.

- New Innovative Brush System – Ensures even and thorough washout for consistent results.

- Dantex Easy Access System – Simplifies operator access for maintenance and setup.

- Automatic Essential Maintenance – Self-cleaning and self-check features to ensure long-term stability.

- Online Connectivity Direct to Dantex – Enables remote diagnostics, updates, and technical support.

The Marathon processing range was specifically developed to complement the New Marathon Plate Technology, while remaining fully compatible with standard Torelief steel-back plates. This innovative system introduces a new level of sustainability and performance to the industry.

With a focus on environmental responsibility and operational excellence, Marathon systems reduce resource consumption and enhance workflow productivity. Dantex’s forward-thinking technology delivers exceptional quality, improved efficiency, and the fastest processing speeds available on the market.

Engineered for the evolving demands of the metal décor and packaging sectors, Marathon plates provide outstanding print clarity, achieving 1% to 95% halftone resolution at 200 lpi for crisp, high-definition results.

The Marathon Plate Range is designed for compatibility with the latest imaging technologies, including inline Esko systems. These plates feature low polymer fatigue, excellent image contrast, and extended run capabilities, ensuring reliability and long-lasting performance.

Each plate is manufactured using a unique polymer formulation that naturally produces a flat-top dot structure during plate making — eliminating the need for additional processing steps. The polymer’s robust composition provides high resistance to friction, ensuring long print runs with consistent quality even at high press speeds.

The result is stable on-press performance, no swelling, and superior ink transfer, making the Marathon Plate Range a powerful choice for printers who demand precision, durability, and efficiency.

Certified to Deliver Excellent & Reliable Service

“Randomsoft Limited has been instrumental in keeping our Kodak CTP machine running smoothly. Their technical expertise and prompt response have saved us countless hours of downtime.”

- Production Manager, Lagos State Printing Corporation

“Since partnering with Randomsoft, we’ve experienced top-tier service support. Their engineers are knowledgeable, reliable, and truly understand the printing industry.”

- CEO, PrintBox Nig. Ltd

“We rely on Randomsoft for all our equipment maintenance and consumables. Their relationship with global dealers ensures we get original parts quickly and at competitive rates.”

- Head of Operations, Printing and Packaging LTD